Late 2023 Daytona Problem

Scroll down to 2023-11-27 Update for the final installment and updates

2023-09-05 - The Problem

During the last few track days in riding the 2020 Daytona 765 moto2, I was having trouble getting the bike to start, both cold and warm. When it finally started, it sounded like it was missing a cylinder for the first 30 seconds or so and I thought I was seeing a tinge of white in the exhaust for that first 30 seconds. The bike ran fine and did not seem down on power, my top speed was actually 1mph faster than what I'd seen before on the front straight (though I was braking slightly later too).

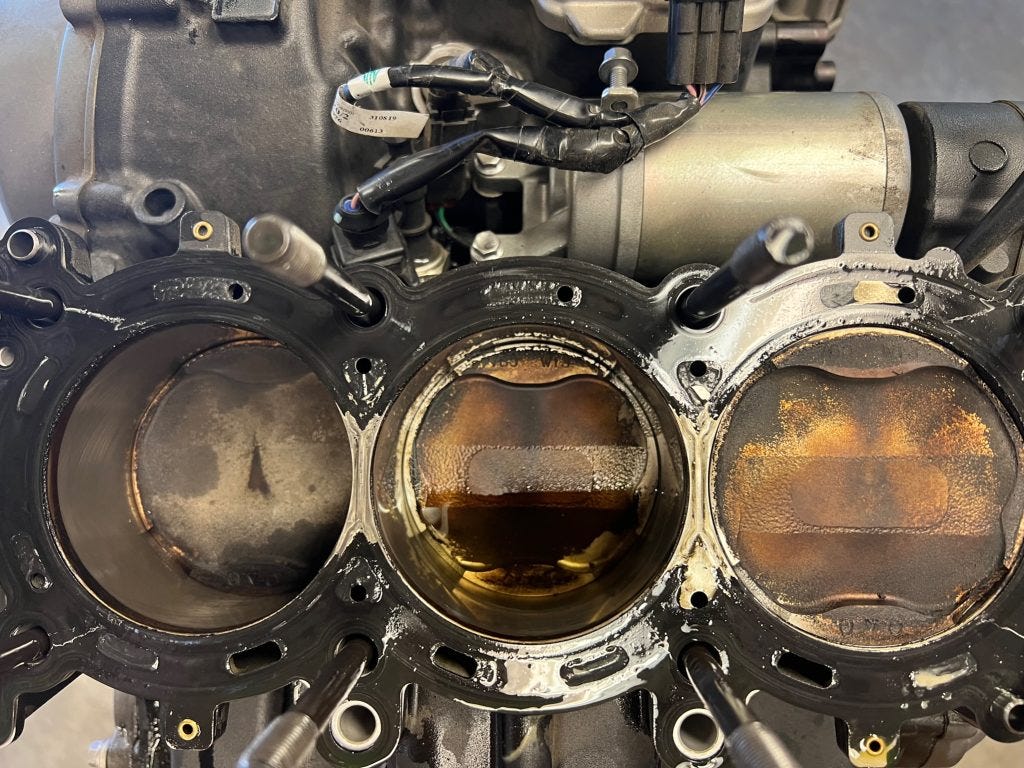

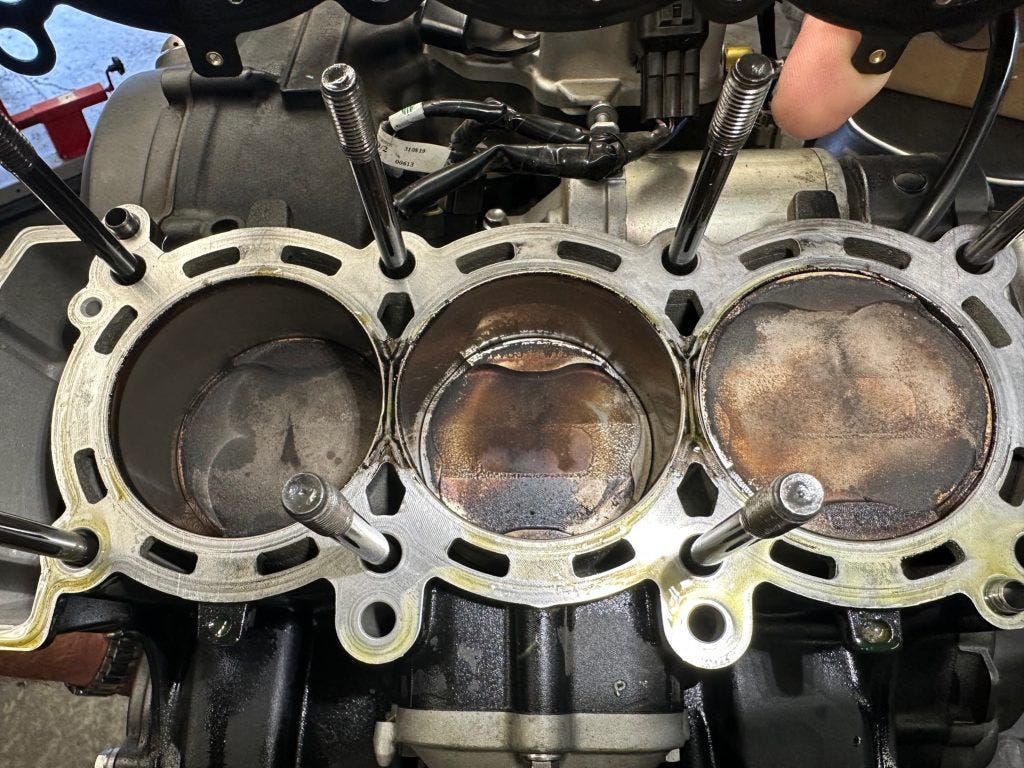

I'd already scheduled my bike to go to my local mechanic (P&M Motorcycles in Petaluma) when I brought the bike home for the Fall and Paul was going to do the valve inspection and a once-over on the whole bike. I described the symptoms and he and I had the same suspicion--a leaky head gasket. A few days later after doing a leak-down test and compression tests, they had the engine out of the bike and the head off and it was very apparent that there was leakage into cylinder #2 from both cylinders #1 & #3 and there was even residual coolant in the cylinder.

Okay, so obviously a head gasket is called for. Since we're in this far, let's do a new camshaft tensioner, cam chain, rings, and pull the cylinders and get them checked, as well as the head of course. By the way, all the valves were in-spec. Right next door to P&M is Engine Dynamics, an esoteric specialty shop that blueprints heads and engineers solutions to motorcycle heads that breathes some more magic into things. Since the head is off, may as well get it checked out for opportunities. As it turns out, ED has done work on 675 & 765 heads, and with some porting and polishing, they have seen up to +5 bhp out of the bikes. This is a nice kind of power because you're not using special fuel, thin head gaskets, etc. that place a lot of additional strain on the engine. This is just power by helping the engine breathe better. What the hell, maybe I can hit low 140-ish mph on the front straight at The Ridge Motorsports Park...

After the initial cleanup and check on the cylinders, it turns out that there appear to be imperfections in the casting. There are a couple of options now: 1) replace the cylinder assembly and *hope* that the replacement is perfectly cast -OR- 2) try to fix the existing casting by cleaning it out, filling it with aluminum-friendly weld, and re-honing it. We are going to try for option 2. If ED can successfully repair the cylinder assembly, then that will significantly reduce the probability of this occurring again. If they aren't able to repair it, then we'll order a replacement set of cylinders from Triumph and hope for the best.

So in sum, yeah, I'm bummed that Triumph had a poor casting for these special, limited edition bikes. On the other hand, it's done nearly 7,000 track miles (11k km) at A group pace and most maintenance has just been consumables. If anyone from Triumph happens to read this, maybe put a message to your casting group and QC to check for the cylinders a little more closely. I love my bike but it was really the first manufacturing disappointment I've had and the head gasket failure could have been prevented.

2023-09-19 Update

ED was able to weld and hone the cylinder assembly so that part is good and likely better than stock so that's encouraging, also considerably less expensive than purchasing new jugs.

ED has also begun the blueprinting process, brief video showing the start of it below. Now lets see if the rest of the parts arrive in time to get the bike back together for my late September track days!

2023-09-21 Update

ED has finished the cylinder assembly and the head is coming along with the blueprinting. I had a fascinating discussion with John who is doing the head work. No photos that I can take with my phone capture what is happening with it but any lips and roughness is being cleaned up. The difference is staggering as he had finished two exhaust and intake areas and had one that was untouched. You can very noticeably feel the 'lip' between mating surface areas, as well as how smooth the intake and exhaust chambers feel. It's a labor-intensive process and they also have the ability to 'flow' the differences (though that won't be necessary with mine as they've done enough of these, they can tell right off hand what's going to make a difference). John showed me the valves and they're all in good shape and they'll test the springs before reassembling as well but so far everything is looking good.

Mike and John operate Engine Dynamics and since all of this is new to me, I had lots of questions but these guys are terrific and put up with all of my questions. I have no intention of getting into this business myself but I like to know how this stuff works and learning about it. It's got a kind of old-world feel inside the shop with lots of parts, raw materials (they can make valves for antique vehicles if need be) but they both have oodles of experience that they can verify. There aren't a lot of shops doing this type of work any longer but they are on the high-end of this sort of work with as much or more experience than most. They can verify their work and they take a keen interest in why something might have failed initially and working to prevent it in the future. They fully understand that there are ways to develop maximum power but that's always a balance between keeping it working as long as possible and know how to weigh that. As I mentioned earlier, this is the kind of work that's attractive to me because it puts less strain on the engine as compared to increasing compression (higher compression pistons, thinner head gaskets, etc.) and it's done in a way that overcomes mass production shortcomings. Granted, OEM manufacturing has come a long way in the last 20 years or so and the benefit of this type of work isn't as great as it was when tolerances weren't as tight as they've become recently but there are still gains to be realized. I also take a degree of pride in supporting this type of work. While it seems like an art to my uneducated familiarity, they have this down as a science.

2023-09-28 - Head Work is Complete

John and Mike at Engine Dynamics have finished up the head work and have reassembled the valves into the head. At this point we're just waiting on Triumph parts, some may be coming from England yet. This would include gaskets, rings, camshaft tensioner, cam chain, etc. While there, Mike & John let me know their recommended coolant--Evans Coolant for Powersports. Apparently one of the ways that engine damage happens is when the coolant boils, at which point it turns to steam. Steam is a poor conductor of heat so consequently those areas in the engine get hotter and can lead to failure. Evans is apparently used in Nascar to deal with extreme heat so that's what I've ordered up.

2023-11-27 Update

I'm a little late in posting the update but the engine is complete, back in the bike, and back to me. It was a big bill but P&M made it hurt as little as possible while it's important to me that they are profitable. The biggest delays were due to waiting on parts and tools to do the work--it turns out that the case has to be split in order to install the new rings and the head. We weren't aware of all the parts that would be necessary to reassemble the engine and several of those had to come from England. As I said, the bike is complete and back to me. When MC Tech can get me in, Mike will install a fresh shock, likely soften the front end a bit more (Ken mostly guides direction on this), and do the engine break-in on the dyno. Hopefully, it'll make its way to him in the next couple of weeks.

I've ordered up the Racetorx thumb brake kit after researching options. Theirs is pretty elegant and I have a few spots on my tracks where I think it would be interesting to try using the rear brake. As much as I've tried to use it while on track with the right foot, I just can't get myself to do it so it'll be interesting to see if I can make it happen with my left thumb. Nearly all of the MotoGP bikes have thumb brakes.

While with P&M, Jesse installed the Braketech ventilated brake pistons and I can't wait to see if those help out with the brake fade I get on the harder braking tracks (Sonoma & The Ridge). If these don't sort out the brake fade, I'll look into ducts and/or the Castrol brake fluid. I'm also considering bypassing ABS as well. I can't find a pre-spec'd kit so I'll likely have to do the measurements and check banjo angles and order a custom kit. I'm not entirely positive about this. I've long espoused the benefits of learning to ride to the bike's electronics but there was an instance in 2023 where the ABS may have gotten in the way. I *could* learn to adapt around it (don't float the front wheel coming out of the Ridge T11 quite as long) but I'm hoping to get to a point where it could be a problem in more instances as I build on my own riding. If there's anything the Tuono has taught me it is being more comfortable with the front end coming up on corner exits.

Another update - I have the i2M TPMS system fully coded up and sensors installed on all 5 wheels and talking to my AiM data logger. This will be a mostly informational thing and it will be interesting to see tire pressures and temperatures at different paces. I've added the tire temps to the SmartyCam display.

I also wired up and tested the GripOne IMU which is supposed to directly output lean and pitch angle into the data stream and will also be available for the SmartyCam stream once it's functioning. After countless hours spent trying to code it in and failing, it wasn't until Mitch Minton did a remote session with me and explained that its 1Mbps CAN bus frequency wasn't compatible with the bike's 500 Kbps native stream (when connected it caused a CAN error on the bike's dash). I do have it mounted and figured out the Italian software to calibrate the sensor. Mounting was tricky as it's ideally mounted under the tank (per the manufacturer) but there simply wasn't room. I couldn't find an elegant way to mount it central to the bike but considering that I'm mostly looking for lean angle and not using it as a part of wheelie control or TC or cornering ABS (of which it is capable), it'll be fine mounted in the tail section of the bike. To mount it, I used a small piece of sheet aluminum that I trimmed to fit in the tail section of the bike (near the EVO4s). The aluminum sheet has a section of closed cell foam underneath it, zip-tied to the plastic tray in the subframe, then the IMU itself is mounted on top of a piece of closed cell foam with a piece of open cell foam and is zip-tied to the aluminum sheet. With this, I'm hoping to minimize the vibrations from riding to provide reasonably accurate lean and pitch angles though I may need to do some smoothing of the data to account for bumps. The back story of this project stems from having native pitch and lean data on the Tuono V4. I compared that to the math channel results on my AiM hardware and revised my math channels to try to smooth the data a little but at higher lean angles the AiM math channel is still quite a bit higher. While this doesn't matter so much on the same bike, I'd like to have fairly consistent and trustworthy data to compare.

I've also replaced an intermittently faulty Stahlbus bleeder valve on the front right caliper. Stahlbus is great to work with and once installed and the initial bleed is done, their bleeders save an amazing amount of time in doing mid-season brake bleeds. Other than this one intermittently leaking fluid from the threads during bleeding, they've been flawless. I mentioned it to them and they quickly sent out a replacement, even though they're over 3 years old.

The tail section of the Daytona has a lot of cabling in there--most of it being related to the AiM data logger and connections, now also the TPMS receiver and the IMU. Since I'm no longer using the OBDII connector to tie into the CAN bus on the bike and am direct-wired, I could clean up some of the earlier wiring. For 2024, I've added two devices that have 4-wire connections to the power and CAN bus, I looked for and found a fairly elegant way to connect using 'GKEEMARS Lever Wire Connectors, Quick Wiring Cable Connector Push-in Conductor Terminal Block (2 in 6 Out)'.

I may also order a fender riser kit that will lift the front fender about 16mm which would give me a little more clearance for tire warmers but more importantly, I'm interested in trying the 125/70 front tire with a 190/60 rear after I burn through my current tire inventory. I honestly hadn't thought about changing tire geometry in years but my recent experience and following adoration for the 125/70 & 200/65 on the Tuono V4 has piqued my curiosity. On the Aprilia, that combination has been great--I feel like I have so much side grip, and [for me] the tire wear has been exceptional, even with an SC1 compound at a respectable pace. With the SC3 200/60 on the TV4, I only get a single day out of the rear. With the 200/65 rear, it had 1 Laguna AFM race, 1.5 days at Thunderhill East, a full day at Sonoma (including 2 sessions with a properly fast rider), and a half day at Laguna before it was spent, and by spent, it was 'shelved' noticeably. With that experience, it's making me think seriously about trying a 125/70 front on the Daytona with a 190/60 rear. Once I start getting low on tires, I may try out the taller tires.

I now have two additional coding harnesses to keep track of so I've labled those and put them into my kit--one for the IMU and one for the TPMS system. I can't imagine that they'll be used often once things are coded up but they take a long time to replace should I misplace or lose them. Into the black Pelican box they go...

So the bike is coming together nicely, it's great to have it back in the garage though that will likely be short-lived as it'll probably spend most of the winter with MC Tech and I'm hoping the thumb brake kit arrives in time for me to install it, otherwise I'll give it to Mike to install. Fingers crossed that GripOne gets back to me soon so I can get the IMU coded up to work with my bike too.

This bike has not been inexpensive, however, it's served me exceedingly well. I've ridden it for nearly 7,000 miles on track (and ~1,000 miles for break-in). P&M told me that all the valves were within spec when they disassembled it so that's encouraging. It's very well-sorted with a lot of love from myself, MC Tech, P&M, and Ken Hill. It's been an excellent data sled having been ridden by some very capable and experienced riders/racers and I've been able to use data from it to improve my own riding. With it being out for the last bit of 2023, it forced me to spend a good bit of track riding time on the Tuono, which has resulted in other improvements that I'll be able to carry over to the Daytona. Riding a torque-rich bike like the TV4 has taught me to be more comfortable with acceleration and high speeds (on a naked bike, no less), helping me build a feel for rear traction on exits by taking advantage of sophisticated TC (no, I'm not just pinning it, but building throttle while feeling the TC start to engage and the feeling from the back when that happens), and how to adjust electronics based on pace and the track characteristics. Figuring out electronics took me a year on this bike, but I have a much better sense of it now. I've also further come to realize that I personally prefer a softer front end on the bike--between the kart track on a stock front end on the Ninja 400 and some fairly soft settings on the Tuono forks, I'm concluding that I like the feeling of the fork being heavily compressed near turn-in. 2024 should be an outstanding season!